@LaurentS

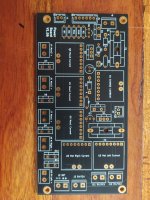

Shopping List is on Github.

Some of the names and links are in German, but I hope you can still find everything.

I have tried to find a link for everything. I hope I have not forgotten anything. And they are all just examples.

All information without guarantee

Motor drivers and motors are still missing.

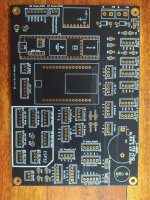

You then need a housing, motors, motor drivers, battery+charger and perimeter transmitter and charging station.

For motors, I would look for defective robotic lawn mowers on Ebay, it's cheaper and you have matching motors right away.

As Bernard has already written, Brushless motors are not yet supported. But that will still be come soon, as I have some myself.

@Bernard

Since I have brushless motors and drivers, I can deal with it. For this, the code has to be modified a little.

Shopping List is on Github.

Some of the names and links are in German, but I hope you can still find everything.

I have tried to find a link for everything. I hope I have not forgotten anything. And they are all just examples.

All information without guarantee

Motor drivers and motors are still missing.

You then need a housing, motors, motor drivers, battery+charger and perimeter transmitter and charging station.

For motors, I would look for defective robotic lawn mowers on Ebay, it's cheaper and you have matching motors right away.

As Bernard has already written, Brushless motors are not yet supported. But that will still be come soon, as I have some myself.

@Bernard

Since I have brushless motors and drivers, I can deal with it. For this, the code has to be modified a little.

Last edited: