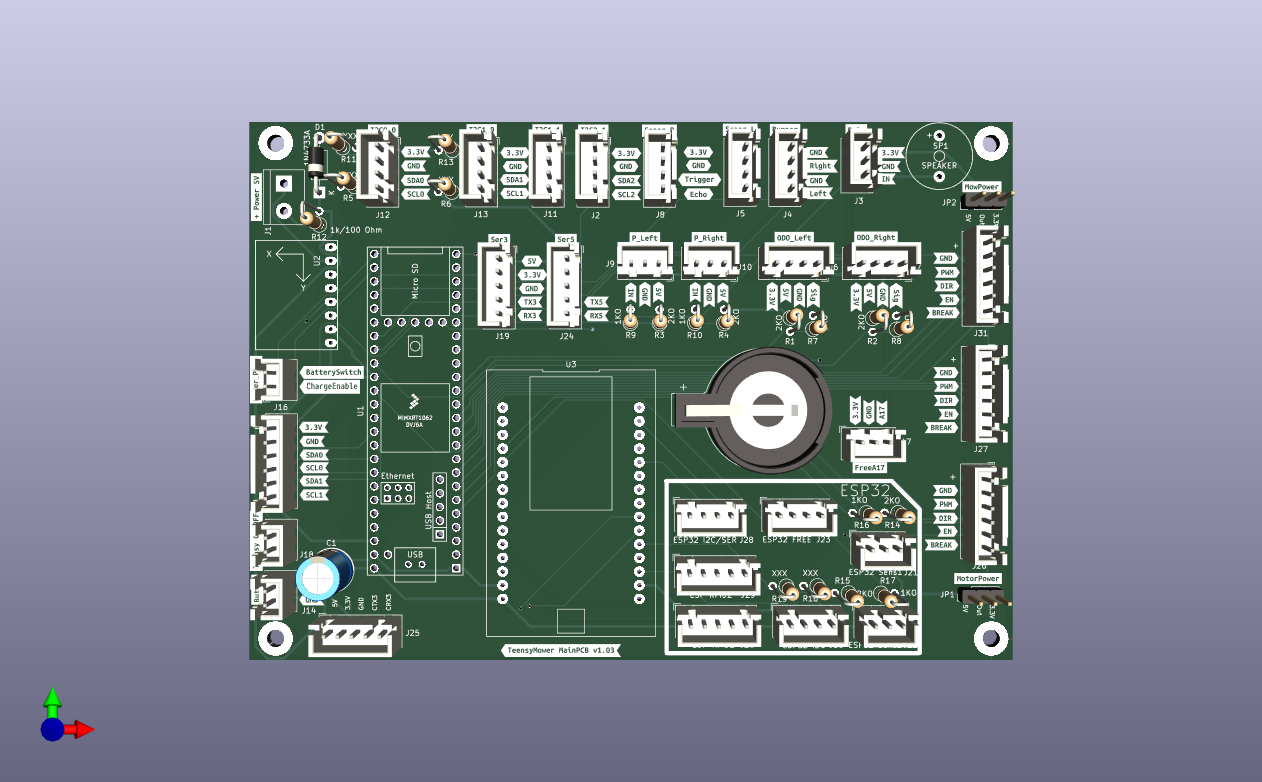

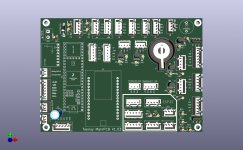

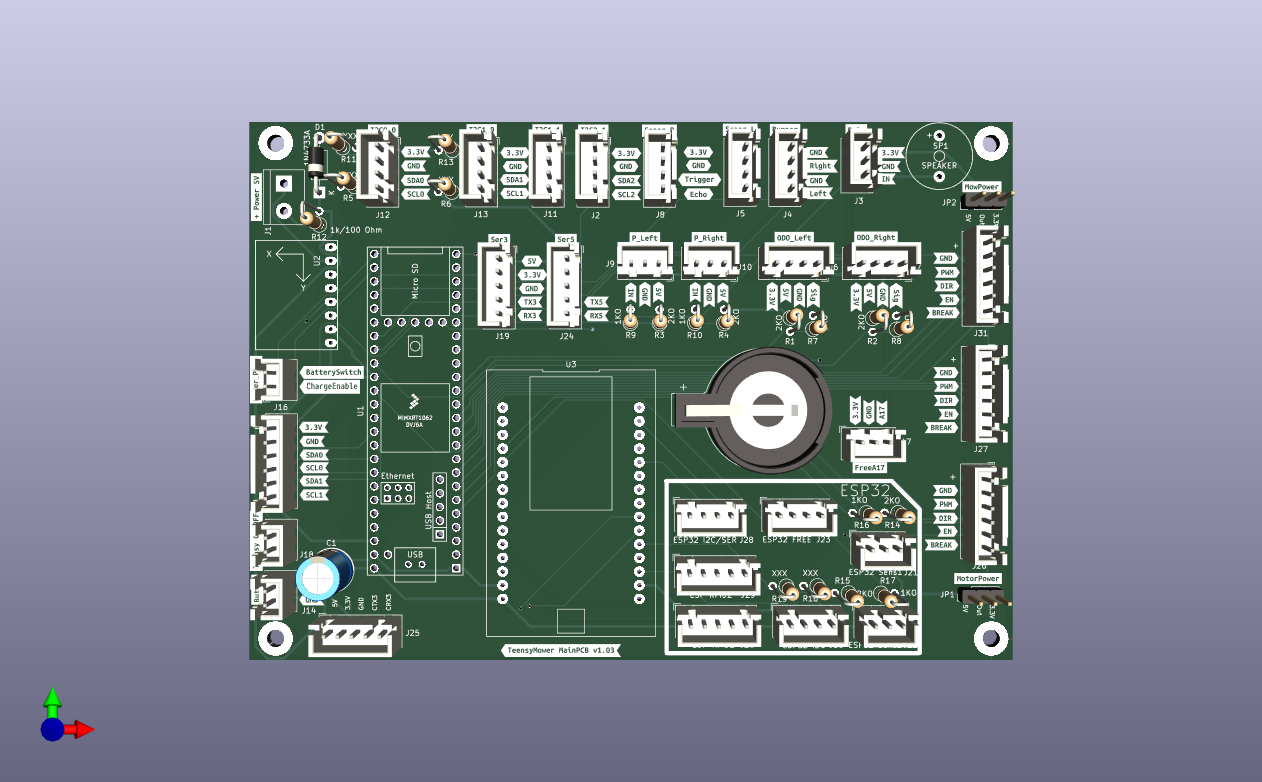

So I have now only corrected the known errors on the PCB, extended and partially enlarged the labelling and sorted the components a little differently in order to optimise the tracks a little.

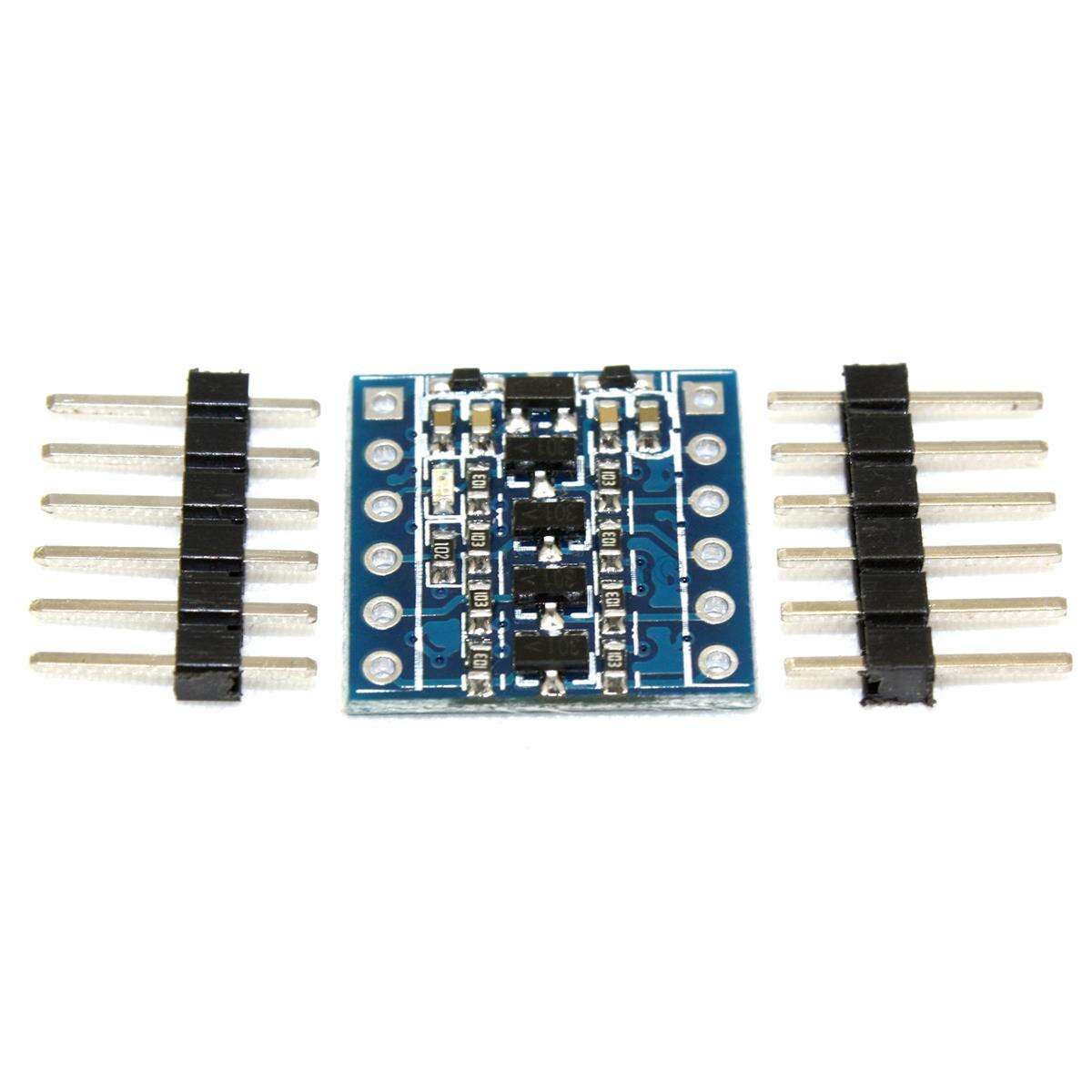

I haven't added the brake pins for the motors yet, the Teensy only has 4 free pins.

I haven't added the brake pins for the motors yet, the Teensy only has 4 free pins.