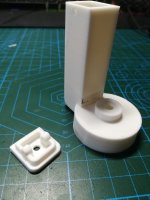

I'm testing an holder with rubber dampers. And just an other idea... I will test it: to tilt the power board for more access, better cooling and more distance from cover.I have printed the PCB holder, it looks good.

Attachments

Last edited: