Hello everyone,

Now that I have all the parts together and the circuit boards are soldered, it's time to mount them in the chassis of the RL2000. Many thanks at this point to Sascha for the circuit boards and to Bernard for the 3D data.

@Bernard Do you have any pictures and hints how to mount the Odo inside the RL2000? As I know, it is needed to dismantle the gear.

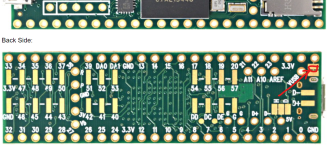

Some time ago I read that you should open a wire on the Teeny board to be able to programme it when it is installed. Unfortunately, I can no longer find the thread.

Now I go ahead by preparing all the connection cables.

All further information is very welcome.

Daniel

Now that I have all the parts together and the circuit boards are soldered, it's time to mount them in the chassis of the RL2000. Many thanks at this point to Sascha for the circuit boards and to Bernard for the 3D data.

@Bernard Do you have any pictures and hints how to mount the Odo inside the RL2000? As I know, it is needed to dismantle the gear.

Some time ago I read that you should open a wire on the Teeny board to be able to programme it when it is installed. Unfortunately, I can no longer find the thread.

Now I go ahead by preparing all the connection cables.

All further information is very welcome.

Daniel