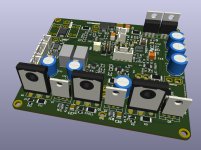

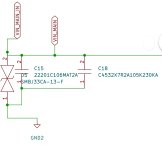

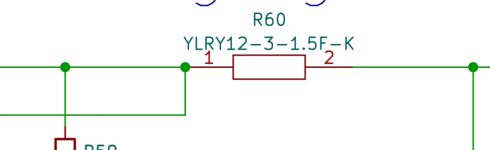

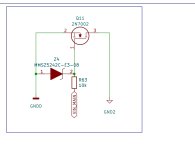

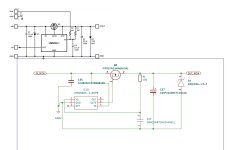

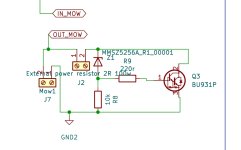

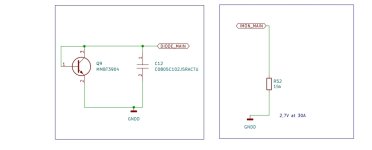

-added optional safety braking resistor circuit for BLDC driver especially for MOW motor.

Why?

Bldc motor act as a GENERATOR when rotating, generated energy need to be dissipated somewhere. If not, it increasing voltage in circuit, electrocuting all electronics.

Mistral.ai

deepai.org/chat

Example worst case scenario:

How many energy will have disc (mow) with diameter 40cm. Mass 1000g rotated with 3000 rpm. Slowed down to 0 rpm in 10s. That disc is connected to generator. How much will rise the temperature of resistor with weight 50g from 20 Celsius. 2 ohm resistor is made from 60% ceramic, 35% aluminum, 5% kanthal?

(...)

The energy dissipated as heat in the 2-ohm resistor is 986.96 J

So, the temperature of the resistor will rise to approximately 44.67 °C.

Generator is given 986.96 J energy to convert to electricity. What will be the final voltage stored in 470uf capacitor?

(...)

So, the final voltage stored in the 470 μF capacitor will be approximately 2049.37 volts.

(Voltage without dumping energy to heat).

(...)

986.96 J energy dumped in to-220 Mosfet not heatsinked over the time of 10s. What will be the Mosfet temperature?

(...)

Estimated temperature rise: ~7402°C (theoretical)

Practical outcome: The MOSFET will likely vaporizing or burning out.

And with heatsink?

If the heatsink is efficient and Rθ_is about 10 °C/W, the MOSFET will reach roughly 987°C

Not possible to survive energy dump without power resistor or dumping energy back to battery.

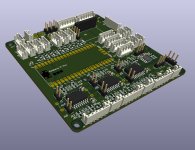

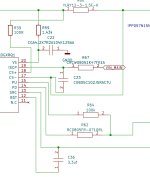

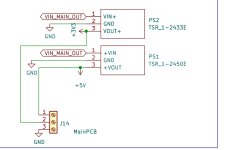

Some of the features can be replaced/dropped as per need.

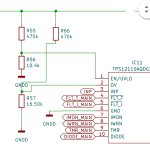

Tps12110 can be replaced by tps48xx chip (higher voltage version) or replaced by 2x ITS428L2

All 3.3v, 5v power supply ics, can be swapped by simplier, cheaper version of circuit/ic.

Ideal diode ICs can be swapped with normal diodes, but then it need to be mounted on heatsink.

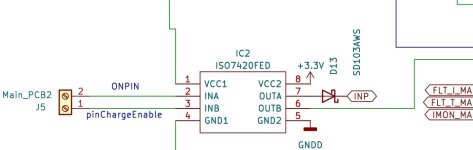

Other Isolators (2 x cheaper) with less lines (ISO6741F), can be used with minor change to the scheme (with failsafe option = low), i just reusing some old IC stocks. DIY.

Jumpers/potentiometer/multiple value of the resistors/capacitor selectable options could be removed, there are just put on PCB for experimental version.

Isolators can be dropped and replaced by voltage translators. Then there is no need to use isolated power supply but = limited protection.

In case of problems with powering Raspberry Pi 5 through GPIO, then Raspberry 5 need to be powered through USB-C port, read more info on post in forum.

The best approach (because of complexity) is to order smt stencil during PCB ordering, order parts separately and assembly in home. Keeped minimum 0805 smt parts size, for easy assembly.

Size of the board <100 mm for cost/manufacturing considerations.

Thermal reliefs are removed (for better electrical connection=higher A). I will assembly PCB on hot plate. If using other methods, please consider readding it. Also hand solder footprints are not selected, if using soldering iron, it is better to replace it normal -> hand solder, and check position of footprints on the PCB, they are slightly bigger.

Or use 0,2mm soldering tin wire and soldering iron:

Use only nylon/plastic screws/cable ties to mount PCBs.

Do not accidentally mix GNDs.

If using cable shielding, connect shield to GND only on one side of PCB.

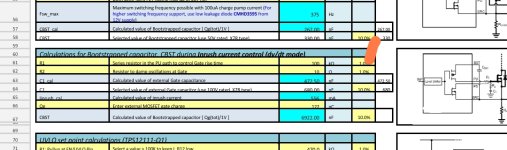

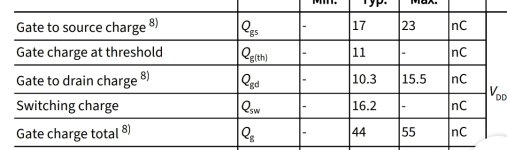

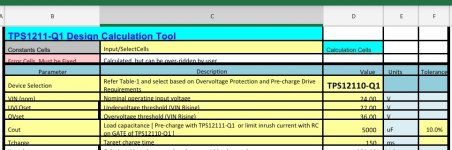

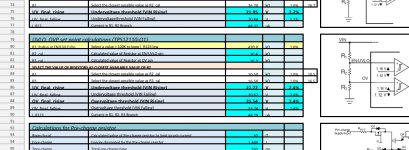

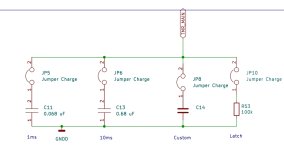

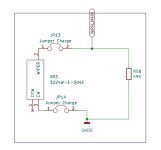

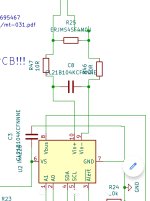

-Parameters can be calculated using attached calculator and value of the resistor can be inputed on empty 0805 smd space. There is also possibility for set the parameters using potentiometers/resistors + jumper (optional).

Jumpers are for isolation of the potentiometer during ohm setting/disconnecting. Resistors can be swapped for potentiometer footprint, but I don't know how potentiometer will behave during vibration when mowing. Not yet tested.

There is possibility to put some digital potentiometer like AD5243/AD5248 etc.

But the safest cheapest solution is just preset values with regular resistors/capacitors that can be calculated using attached xls calculator.

-Changed layout for Increasing tracks width.

-some safety diodes/mosfet on scheme are removed.

(charger side)

If You need it back please look at older circuits then DIY.

The original charging circuit in ChargePCB v 1.0

Is not optimally designed! Because there is voltage drop on diode + Mosfet

In example:

Vloss = I x Rds

Given:

Rds=0,2 (IRF9540)

I=5A

So, the voltage loss across the MOSFET is 1V.

Diode : 0,6 (even Schottky) + 1V = 1,6 V (!)

So 7s lion will be always charged to 27.8V ~ 70% capacity. Using 29,4V charger.

Introduction Having many 18650 battery cells to charge, I bought a few dirt cheap TP4056 modules (0.22 EUR per piece) and discovered that they are "not designed for"

blog.deconinck.info

That diode/mosfet:

-could cause the voltage oscillation with some chargers.

- YouTube

(...)

-could cause problem with BMS. Some models start balancing cells from certain voltages. That is never reached because of diode. (... )

(...) Slow charging causes phase separation. - Martin Z. Bazant | Stanford University | Physics of next generation batteries.(...)*

(...)

The problem with this circuit is that many boards have discharge cut-off circuit(dw01) cant be used as diode will block the discharge completely.

(...)

I did the same test 10 years ago with the same results. A very confused controller.

(...)

If you keep permanently 1.1 Volt across a Ni-MH cell, or 1.8 Volt across a Lead-acid cell, both cell will stay at 25% state of charge without damage.

If you keep 3.8 Volt permanently across a Li-ion cell, it will keep at 25% state of charge, but after a couple of weeks it will be either dead or damaged (increased Ri).*

-When chargers don't cut charging in certain time. With Li-ion battery cells could be damaged:

*Comments in above video.

-With high current chargers voltage drop need to be huge (bigger diode, bigger loss on Mosfet).

(...)

The main circuit diode:

The safety circuit based on Tps1211 have additional Mosfet acting as a ideal diode.

If using Li-on battery, the best solution is to use safe charger that will not burn anything:

- YouTube

Lets take a look at the example charger:

-3-step charge control with current detection

-Universal input voltage

-Wake up and low current start-up of deeply discharged batteries

-Safety indication and protection: Against reverse polarity, short circuit, charging battery packs with the wrong number of cells and safety timer run-out.

Approvals

Medically certified => isolated.

Safety:• UL approved• EN 60601-1 ed. 3.1• Home healthcare EN 60601-1-11• Household safety, EN 60335-1 & -2-29EMC:• EN 60601-1-2 ed. 4

Or other PROTECTED chargers. That all the charging parameters can be adjusted.

And then compare to the quality of other (cheap), no-name power supply from channel:

- YouTube

(...)

"A self-baking, thermal drifting, interference generating, electrocution house burner..."(...)

- YouTube

- YouTube

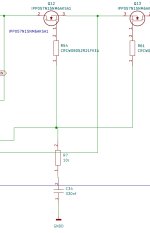

So what is the choice on the ChargePCB?

-leave it as it was originally =>battery is not fully charged (because of diode+mosfet). Please add missing components on schematics DIY.

-add chip like NCV68261 + n-Mosfet, DIY

-add ITS428L2 + diode, DIY

-skip all the circuits on ChargePCB (except basic one) and leave all the safety circuits on the SAFE CHARGER side (default version).

Charging circuit => is the charger job.

-Xt30 charging input port (will be basic protected by diode and blowing fuse: according to the scheme):

Introduction Having many 18650 battery cells to charge, I bought a few dirt cheap TP4056 modules (0.22 EUR per piece) and discovered that they are "not designed for"

blog.deconinck.info